No matter how much you learn about packaging, you will always find yourself needing to know more. However, it doesn’t mean that you should give up on learning. The more you learn, the more you advance in the industry.

This article is just another piece of information to help you know some necessary terms you should have in your mind when buying packaging materials. These terms cover different aspects of stretch wrapping.

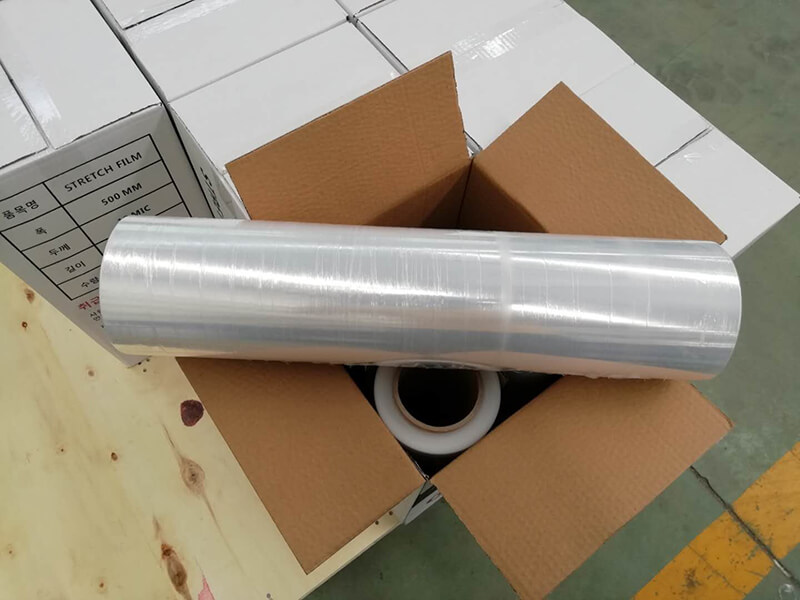

Hand stretch wrap

You may already know about the stretch wrap. It is a thin polyethylene film used to secure loads of products and shipments before shipping. You can use the elasticity of this film to pull it and wrap it around the shipment tightly. The strength of its wrapping comes from the tension.

Hand stretch wrap is applied with the help of hands. Because it required manual action, this film comes a bit pre-stretched. You can secure smaller pallets or lower volume loads using this stretch wrap film.

Machine stretch wrap

The stretch wrap film you engineered to work with machines is known as machine stretch wrap. A stretch wrap film is a large platform that spins the pallet. A mechanical arm holds and pulls the film while wrapping it around the pallet.

Since this stretch wrap film has to be used on a machine, it doesn’t come pre-stretched. That is why it is a bit tougher than the hand stretch wrap film. The machine stretch wrap film is commonly used in fulfillment centers and warehouses, where packing personnel has to wrap larger pallets. This film, when used on the machine, can stretch up to 300%.

Blown stretch wrap

The process of blowing heated resin vertically into a bubble helps form blown stretch film. The manufacturing personnel then cool it down using cold air and transform it into rolls of wrap. The film produced through this technique is a little cloudy and experiences friction during unrolling and stretching.

The upside of the blown stretch wrap has extra stretch memory and tear-resistance. That is why this film is ideal for wrapping heavier loads. It works better on a stretch-wrapping machine.

Cast stretch wrap

Cast stretch wrap is created by running a sheet of hot resin through a path of chilled rollers. This procedure produces a stretch wrap film that is clearer than blown stretch wrap film. It also offers less friction compared to the blown stretch wrap film.

Due to these features, this film is ideal for packaging applications that shouldn’t hide barcodes and other information on the pallets and shipments. Due to less friction, unrolling and stretching of this film doesn’t give away too much noise.

The pitfalls of this stretch film include less stretch memory and less tear resistance. However, it is still a suitable choice for machine stretch wrapping applications.

Pre-stretch wrap

As the name suggests, this stretch film comes pre-stretched up to its total capacity. This film is ideal for manual applications. The purpose of pre-stretching a stretch wrap film is to increase its ability to ensure load tension. The most significant advantage of using this film is that it requires less hand strength during application.